Featured Products

- Bridge Saws

- Used Equipment - Bridge Saw

- Shop Equipment

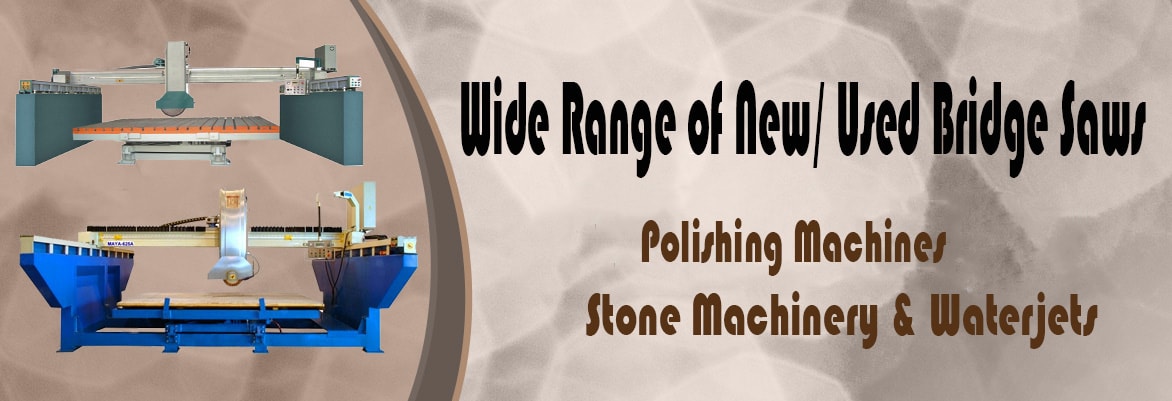

- Bridge saw MAYA 625A

- Spare Parts

- Quarry Equipment

Equipments

- Bridge Saws

- Granite Bridge Saw

- Marble Bridge Saw

- Used Bridge Saws

- CNC Bridge Saw

- Powered Hydraulic Table

Bridge Saws Machines for Sale in Bridge Saws, USA

The Ultimate Guide to Bridge Saws for Granite Cutting

While cutting granite, marble, or other hard stone, a suitable bridge saw is crucial for precise and efficient work. Bridge saws are specialized equipment for clean and exact cuts in granite, marble, and other large natural stone plates. This article describes the various types of bridge saws, their application in cutting granite, and the optimal method of selecting the most suitable bridge saw machine, particularly in the USA. We will also mention some popular models, such as the Maya bridge saw, and address some of the most important things to consider while searching for bridge saw machines. By the time you finish, you'll have a clear idea of how to select the best bridge saw to suit your project requirements.

What Are Bridge Saws?

A bridge saw is a cutting tool found mainly in cutting granite, marble, quartz, and other hard stones straight, accurately, and at angles. These machines are designed with strong motors and heavy-duty blades to handle the hardness of granite without being damaged or broken in the process of cutting it. The saw blade, usually diamond-tipped, is fitted on a bridge-shaped frame, which travels along the stone slab and cuts it straight and smooth. These are largely fitted with computer numerical control (CNC) systems, so intricate cuts may be programmed to high accuracy.

Choosing the Right Bridge Saw Machines in the USA

When you are searching for a bridge saw machine in the USA, there are certain things you should consider:

Cutting Speed and Blade Size:

Test how quickly the saw cuts and what diameter blade it can accommodate. Wider blades can cut deeper, which could be an advantage with thicker slabs of stone.

Software and Automation Features:

New saws for bridge sawing typically come with precision cutting software. Select models with easy-to-use touchscreens and automatic settings.

Machine Structure and Strength:

Look for a machine with a sturdy beam and frame, if possible, castings for added strength. A stiff frame minimizes vibration, enhancing cut quality and increasing machine life

Power and Motor Quality:

Advanced motors make granite cutting more efficient and double the blade life. Select equipment with good accessories like frequency converters and branded motors for consistent performance.

Warranty and Support:

It's important to verify the warranty details, especially regarding coverage for the blade motors and other crucial parts. Choose suppliers who offer help with installation, training, and responsive after-sales service here in the USA.

Additional Features:

Automatic lubrication systems, dust covers, and water cooling systems enhance machine longevity and operator convenience. Some models have multi-axis cutting (3-axis, 4-axis, or 5-axis) for complex cuts and bevels.

Maya Bridge Saw – Popular Bridge Saw Model

The Maya Bridge Saw is one of the popular models that are renowned for their strength, ease of use, and sturdy performance. The majority of the granite fabrication workshops opt for this with its combination of traditional strength with modern features like user-friendly touch controls, computer-aided cutting, and efficient water cooling. The machine is best suitable for small to medium-sized workshops that require cost cost-effective and dependable solutions.

Why Purchase a Bridge Saw for Granite?

Granite is a dense, difficult natural stone that is challenging to cut. The Bridge Saw for Granite is designed to overcome this difficulty by providing:

- Accuracy: Clean and precise cuts reduce waste and enhance product quality.

- Efficiency: Increased cutting rates enhance production potential.

- Versatility: Capabilities for cutting multiple stone materials and dimensions.

- Safety: Water cooling systems and dust suppression protect equipment and operators.

Get the Right Bridge Saw

The right granite bridge saw machine will have your fabrication go smoother, more accurately. Whether you are searching for a manual, semi-automatic, or CNC bridge saw, being aware of the features and applications of each will help you in selecting the most suitable bridge saw machine for granite cutting. If you need bridge saw machines for sale in the USA, consider such good quality models as the Maya bridge saw, optimized to cut hard stone. In addition, listen to cutting capacity, automation, durability, and after-purchase support to ensure your investment is a long-term pay-off.