Featured Products

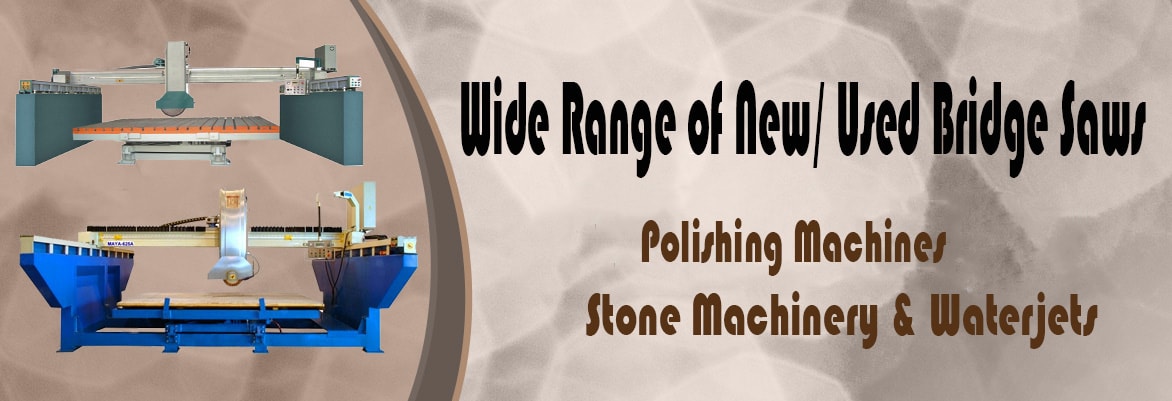

- Bridge Saws

- Used Equipment - Bridge Saw

- Shop Equipment

- Bridge saw MAYA 625A

- Spare Parts

- Quarry Equipment

Equipments

- Bridge Saws

- Granite Bridge Saw

- Marble Bridge Saw

- Used Bridge Saws

- CNC Bridge Saw

- Powered Hydraulic Table

Granite Bridge Saw Machine for Sale in USA

Granite Bridge Saw – A Must-Have Tool for Stone Cutting

Granite and marble cutting involves precision, strength, and suitable machinery. The possession of a granite bridge saw can accelerate your stone cutting operations to become quicker and more precise. Such machines find extensive application within the stone business for cutting granite and marble slabs with neat edges and impeccable shapes. This article will break down what a granite bridge saw is, the way it functions, the smart thinking behind purchasing a used granite bridge saw, and the key things to keep an eye out for when you're in the market for one.

What Is a Granite Bridge Saw?

A granite bridge saw is a cutting machine used to cut massive slabs of stone such as granite, marble, and quartz. It is referred to as a bridge saw since the head cutting travels along a bridge-shaped support structure that passes over the slab of stone. These tools also have great power, force, and the capability to undertake heavyweight cutting jobs. This produces tidy, neat, and sharp straight cuts without variations. The prime elements of the bridge saw include:

- A motorized blade

- A bridge frame

- A cutting table

- A control panel

Advantages of Using a Bridge Saw for Granite

Here are some of the top reasons to use a bridge saw for granite:

- Precise, clean, straight cuts every single time.

- A much faster cutting process compared to manual cutting.

- More precise control over the size and shape of your cuts

- A lower chance of the granite cracking or breaking

Benefits of Buying a Used Granite Bridge Saw

Buying a new machine can be costly, so a used granite bridge saw can be an excellent decision for many companies, especially smaller enterprises. Used machinery is affordable and, if well-maintained, can also offer superior performance. Here are several benefits:

- Cost Savings: Buying a brand-new granite bridge saw is expensive. A used granite saw is significantly less expensive and can be used in tight budgets.

- Quick Availability: New machinery would take months or weeks to arrive. A used granite bridge saw can be shipped immediately in most cases.

- Lower Depreciation: Existing machines have already depreciated the most, so their value retains better over time.

- Proven Reliability: If a machine has been running fine for years, it is likely that it will continue to run just fine when maintained. Just be sure to check out the saw prior to buying and request maintenance records.

Granite Bridge Saw for Sale – What to Look For?

If you're looking for a granite bridge saw for sale, there are a few important features to look for:

- Cutting Capacity: Ensure the saw is capable of cutting the size and thickness of granite slabs you typically work with.

- Blade Type: Examine the size and composition of the blade. The diamond blade is usually employed to cut granite.

- Automation: Some bridge saws are manual, while others may be semi-automatic or automatic. Pick one according to your requirements.

- Condition: If it's a second-hand granite bridge saw, inspect for wear and tear. Examine the motor, cutting head, rails, and control system.

What About the Marble Bridge Saw?

A marble bridge saw is essentially the same type of saw as a granite bridge saw, but it will often use slightly different blades due to the softer composition of marble. If you work with both granite and marble, consider a bridge saw that can work with multiple types of stone. Certain bridge saws are multi-purpose and have adjustable options, so you can use them to cut marble, granite, quartz, and even ceramic tile.

Tips for Maintaining Your Granite Bridge Saw

Regular maintenance increases the machine's lifespan, be it a marble bridge saw or a granite cutter. Here are some maintenance tips for your granite bridge saw:

- Regularly clean the water tank to avoid sludge.

- Ensure proper blade alignment to prevent uneven cutting.

- Grease moving parts to minimize friction.

- Regularly check the motor and belts for wear.

Finding the Best Granite Bridge Saw

Whether you are looking for a used granite saw or purchasing a new granite saw for sale, knowing how they operate and what to look for will help you make the most informed decision. A good granite saw can cut the granite quickly and more accurately. And if you're just starting, purchasing a used granite saw can provide you with all these advantages at a very low price. By taking into account motor power, blade suitability, automation capabilities, and construction quality, you can choose the appropriate bridge saw to suit your level of production and provide fine stone cutting performance.

So If you are searching for Granite bridge saw, Bridge saw for granite, Used granite bridge saw for sale, and Granite bridge saw for sale Then contact Us.