Featured Products

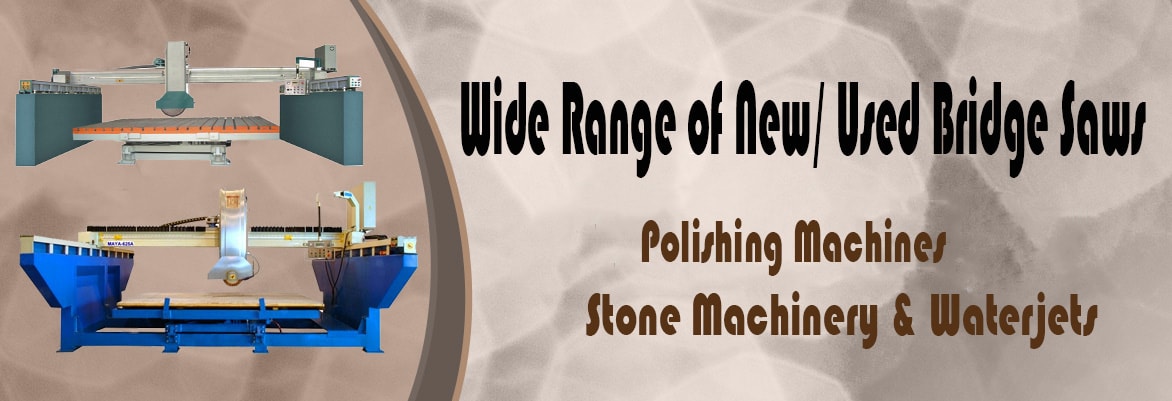

- Bridge Saws

- Used Equipment - Bridge Saw

- Shop Equipment

- Bridge saw MAYA 625A

- Spare Parts

- Quarry Equipment

Equipments

- Bridge Saws

- Granite Bridge Saw

- Marble Bridge Saw

- Used Bridge Saws

- CNC Bridge Saw

- Powered Hydraulic Table

Powered Hydraulic Table

Powered Hydraulic Table Systems: Efficiency to the Next Level

Powered or hydraulic lift tables are crucial pieces of machinery used in the majority of industrial, warehouse, and workshop environments. They provide a convenient and productive way to safely lift, lower, and position heavy loads, minimizing physical strain and maximizing overall productivity. This article sets out to describe what a powered hydraulic table is, how a hydraulic table system works, usual applications, and the principal benefits of hydraulic lift tables in all industries.

What is a Powered Hydraulic Table?

A Powered Hydraulic Table is a mechanical lifting device for lifting, lowering, and positioning heavy equipment or materials with minimal human strength. In contrast to manual lifting, powered hydraulic tables provide a level and adjustable surface to manage materials more efficiently and securely. The table is equipped with a leveled surface on which the load is placed, and a hydraulic component that governs its vertical motion. These tables are ideal for tasks such as assembly line work, loading/unloading, material transport, and ergonomic positioning of workpieces.

How a Powered Hydraulic Table System Works?

A Powered Hydraulic Table System consists of many components that act together to lift and lower heavy objects. The major components of the system are:

- Hydraulic Cylinder: This is the core component. When liquid is pumped into the cylinder, it creates pressure that causes the piston to move, raising the table.

- Electric Motor or Foot Pump: Most powered versions depend on an electric motor to automatically apply pressure. For manual versions, a foot or hand pump is used.

- Control Pedal or Switch: This allows the operator to raise or lower the table accurately.

- Platform/Tabletop: The flat surface on which the products or materials are placed

- Scissor Legs or Lifting Arms: These hold the table and open and close depending on the motion of the hydraulic cylinder.

What is a Hydraulic Lift Table?

A Hydraulic Lift Table is one of the powered hydraulic tables whose purpose is to vertically raise loads. It's widely used in environments where height changes are required in the course of work processes. These lift tables also go by the name scissor lift tables as a result of their X-shaped arms for lifting. Whether lifting products to a conveyor or lowering parts for inspection, hydraulic lift tables make the job much easier and reduce the amount of physical labor.

They are used for:

- Adding pallets to convenient working heights

- Loading and unloading heavy boxes

- Equipment settings for maintenance

- Lifting machinery for repair

Key Benefits of Using a Powered Hydraulic Table

Some of the key benefits of employing a powered hydraulic table in industrial and business settings include:

- Enhanced Safety: Manual lifting is likely to lead to injuries such as muscle strains and back pain. A powered hydraulic table reduces the amount of physical effort required and the likelihood of workplace accidents.

- Increased Efficiency: By mechanizing the lifting process, work is completed sooner. Workers can spend fewer hours on lifting and more time on useful work.

- Improved Ergonomics: The hydraulic table equipment that is driven by an electricity source allows the surface to be lifted or lowered to the best working position.

- Versatility: From factory production dealing with raw materials to storing products in a warehouse, hydraulic lift tables are most appropriately designed for extensive use in many industries.

- Durability: These systems are built to withstand heavy loads and are made from strong materials that last a long time with minimal maintenance.

| wireless pendant remote | wired controller box | Complete system |

Choosing the Right Hydraulic Lift Table

When selecting a hydraulic lift table, remember the following:

- Load Capacity: Ensure the table can carry a load that is heavy enough to lift the maximum weight you plan to lift.

- Lift Height: Choose a machine that lifts to the desired height of operation.

- Platform Size: The platform must be big enough to accommodate the materials or tools you will be using.

- Power Source: Choose between electric or manual operation, depending on your requirements.

- Mobility: Certain tables are fixed, but others are wheeled to facilitate ease of movement across the work area.

Powered Hydraulic Table is a Smart Investment

Powered Hydraulic tables are a must-have equipment in contemporary material handling and industrial processes. Because of their smooth, safe lifting of heavy loads, with ergonomic advantages and efficiency, they are a necessity in warehouses, factories, workshops, and beyond. Learning the operation of these hydraulic lift tables and their uses can assist experts in making appropriate choices to improve workplace safety and performance. If you need to streamline your material handling operations, invest in a powered hydraulic table system. It's a cost-efficient, multi-purpose, and robust system that benefits both your workers and your profits.